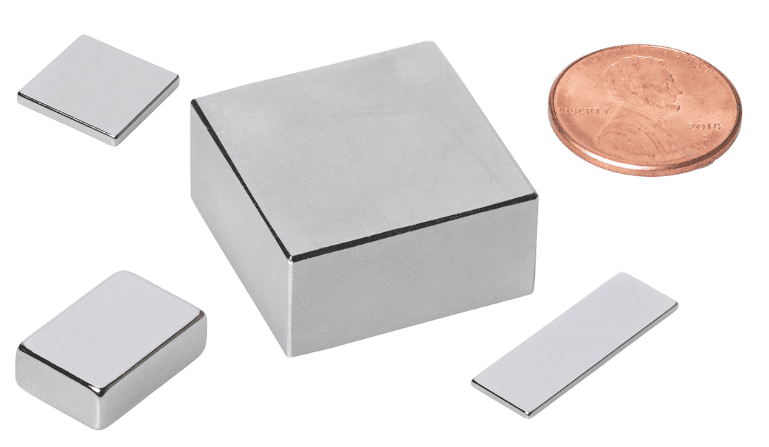

Neodymium Block Magnets

Overview

Adams offers neodymium magnets in square and rectangular blocks. These neodymium iron boron magnets are widely used for motor, sensor and holding applications.

Features

- Neodymium magnets are the most powerful commercially produced magnets.

- Neodymium magnets are hard and brittle and may chip or break if dropped.

- Adams Neodymium ring magnets are magnetized through the thickness.

- Uncoated neodymium magnets may corrode in humid conditions.

- Operating temperatures vary among material grades. For a comparison of neodymium material grades, please visit our chart of material properties.

Rectangular Neo Product Specifications

Contact us at 800-763-4795 if you don't see what you're looking for in this brief listing.

| Item# | Thickness | Width | Length | Grade | Plating | Pull lbs |

|---|---|---|---|---|---|---|

| 50C0189 | 0.060 | 0.240 | 0.750 | 3512 | nickel | 2.3 |

| 50C0311 | 0.060 | 0.375 | 0.375 | 3512 | nickel | 1.9 |

| 50C0799 | 0.060 | 0.375 | 0.375 | 4212 | nickel | 2.3 |

| 50C0151 | 0.250 | 0.125 | 0.125 | 3020 | nickel | 0.8 |

| 50C0080 | 0.250 | 0.500 | 0.750 | 3512 | zinc | 12 |

| 50C0338 | 0.100 | 0.250 | 0.250 | 3512 | nickel | 2.00 |

| 50C0233 | 0.250 | 0.750 | 0.750 | 3512 | none | 18 |

| 50C0327 | 0.500 | 1.000 | 1.000 | 3520 | nickel | 45 |

| 50C0159 | 0.500 | 2.000 | 2.000 | 4512 | nickel | 100.00 |

Stepped Neodymium Block Magnets

Ask us about neodymium block magnets with a stepped perimeter. The stepped magnet shape provides an excellent attachment solution for several applications. They often avoid the need for glue or screws if the tongue or groove can slide into a mold, for example.

Handle with care!

Please use caution when handling magnetized neodymium magnets, their exceptional magnetic force may cause them to attract to metal (or to each other) so strongly that fingers in their path could prove painful.

Gluing Neodymium Magnets

Neodymium magnets are often assembled into products using strong adhesives such as Loctite 325. Make sure that all contact surfaces are clean and dry prior to bonding. For more information on gluing magnets, read our whitepaper.

Contact Us

Adams is ready to be a part of your products with off-the-shelf and custom applications. Contact us to find out more.